Core Craftsmanship for PPF Compatibility with Radar & Cameras

Achieving PPF compatibility with NEV radar and cameras requires a systematic approach, combining precision cutting, professional installation, and strict quality control. Below are the key craftsmanship elements:

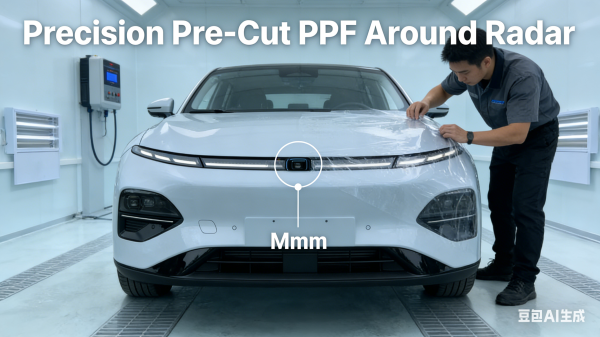

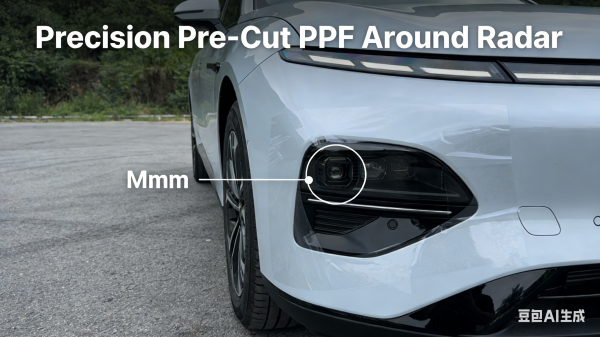

1. Radar & Camera Position-Aware Precision Cutting (No Disassembly Required)

Traditional PPF installation often involves on-site cutting, which risks damaging radar and camera components or leaving imprecise edges that block signals. The solution is vehicle-specific precision pre-cutting using advanced laser scanning technology:

-

3D Vehicle Scanning Database: Reputable PPF brands build a comprehensive 3D scanning database of mainstream NEV models (e.g., Tesla Model 3/Y, BYD Han/Tang, NIO ET5/ET7). This database accurately maps the location, shape, and angle of every radar and camera, ensuring pre-cut PPF pieces fit perfectly around these components .

-

No Disassembly, Zero Damage: Pre-cut PPF eliminates the need to remove bumpers, mirrors, or other body parts, avoiding damage to delicate ADAS wiring and sensors. For radar covers and camera lenses, the PPF is precisely cut to leave these areas uncovered or to fit seamlessly around their edges, ensuring unobstructed signal transmission .

-

Laser Cutting Precision: High-precision laser cutting ensures the PPF edges are smooth and accurate to within 0.1mm, preventing gaps or overlaps that could trap dust, cause peeling, or interfere with signals. This level of precision is critical for radar areas, where even a small misalignment can disrupt signal propagation.

![]()

2. Signal-Transparent PPF Material Selection

The material of the PPF itself is a key factor in radar and camera compatibility. Inferior PPF may contain metal coatings or fillers that block electromagnetic signals (e.g., millimeter waves). The ideal PPF for NEVs must meet strict signal-transparent requirements:

-

Metal-Free Aliphatic TPU Base Material: High-quality NEV PPF uses metal-free aliphatic TPU (thermoplastic polyurethane) as the base material. Aliphatic TPU not only offers excellent scratch resistance, self-healing properties, and anti-yellowing performance but also has low dielectric constant (ε < 3) and low loss tangent (tanδ < 0.01), ensuring over 98% radar signal penetration . Avoid PPF with metalized coatings, as these act as signal shields.

-

Optical Clarity for Camera Compatibility: For PPF applied near camera lenses (e.g., front windshield PPF), optical clarity is paramount. The film must have high transparency (≥90%) and no distortion, ensuring the camera can capture clear images without glare or blurriness. Premium PPF uses nano-coating technology to maintain optical clarity while resisting UV rays and water spots.

-

Lightweight yet Durable: To align with NEV lightweight design, high-quality PPF weighs around 127g per square meter—15% lighter than traditional PPF (150g+/㎡). This reduces overall vehicle weight gain (full-body PPF adds only ~3kg, equivalent to a small backpack) without compromising protection, ensuring no negative impact on battery range .

3. Professional Installation with ADAS Calibration Checks

Even the best pre-cut PPF and signal-transparent materials can fail if installed improperly. Professional installation with ADAS calibration checks is essential:

-

Cleanroom Environment: PPF installation should be performed in a Class 4 dust-free workshop (≤5 dust particles per cubic meter) with controlled temperature (20-28℃) and humidity (40%-60%). This prevents dust, debris, or moisture from getting trapped between the PPF and paint, which could cause bubbles or affect adhesion—issues that are particularly problematic near radar and camera areas .

-

Wet Positioning + Heat Shaping Technique: For curved surfaces (e.g., bumper radar areas, mirror cameras), installers use a “wet positioning + heat shaping” method. A small amount of specialized installation fluid helps position the pre-cut PPF accurately, while a heat gun (set to a safe temperature to avoid damaging paint or sensors) softens the film to conform to the body’s curves. The film is then pressed firmly to remove air bubbles and ensure tight adhesion .

-

Post-Installation ADAS Calibration & Testing: After PPF installation, a critical step is ADAS system testing and calibration. Technicians use professional diagnostic tools to check radar signal strength, camera image clarity, and the functionality of ADAS features (ACC, AEB, lane-keeping). If any deviations are detected, calibration is performed to ensure the systems work as intended. This step guarantees that the PPF has not affected signal transmission .

How to Choose the Right NEV PPF (Key Considerations)

To ensure your NEV’s PPF doesn’t interfere with radar and cameras, keep the following in mind when making a selection:

-

Verify Signal-Transparent Certification: Ask the supplier for test reports proving the PPF’s radar signal penetration rate (should be ≥95%) and dielectric constant/loss tangent values. Avoid products without clear certification.

-

Check NEV Model Compatibility: Confirm that the PPF brand has a pre-cut database for your specific NEV model. This ensures the film fits perfectly around radar and camera components without on-site cutting .

-

Choose Authorized Installers with ADAS Expertise: Select a certified installation shop with experience in NEV PPF installation and ADAS calibration. Ask to see their dust-free workshop, training certificates, and customer reviews.

-

Review Warranty Coverage: Reputable brands offer electronic warranties covering yellowing, peeling, cracking, and signal interference issues. Ensure the warranty is traceable (via VIN number) and covers both materials and labor .

Conclusion: Protect Your NEV Without Sacrificing ADAS Performance

For NEV owners, PPF is not just a paint protection measure—it’s an investment in preserving the vehicle’s value and performance. The key to avoiding radar and camera interference lies in choosingsignal-transparent aliphatic TPU PPF, leveraging vehicle-specific precision pre-cutting, and trusting professional installers with ADAS calibration capabilities.

By prioritizing these craftsmanship elements, you can enjoy the peace of mind that comes with comprehensive paint protection while ensuring your NEV’s advanced driver-assistance systems operate flawlessly. Don’t let the fear of signal interference hold you back—with the right PPF solution, you can protect your NEV’s beauty and intelligence at the same time.

Frequently Asked Questions (FAQs)

Q1: Will PPF on the front bumper block millimeter-wave radar signals? A1: No—if you use metal-free, signal-transparent PPF with precision pre-cutting around the radar area. High-quality PPF has a radar penetration rate of over 98%, ensuring no impact on radar functionality .

Q2: Can PPF be applied near the front windshield camera? A2: Yes, but only use PPF with high optical clarity (≥90%) that is pre-cut to fit around the camera lens. Avoid covering the lens itself, and ensure the installer checks the camera’s image clarity post-installation.

Q3: Is ADAS calibration necessary after PPF installation? A3: Yes—even with pre-cut PPF, minor adjustments during installation can affect sensor alignment. Professional calibration ensures ADAS features like ACC and AEB work correctly .