Magicar offers a dedicated film cutting machine for TPU PPF. The machine features a dual-arm film application design, making assembly simple and usage convenient. It boasts a cutting speed of up to 800mm/s and comes with 9 built-in pressure wheels to ensure precise film application. The intuitive touch panel and operational buttons allow for easy data viewing. With excellent convenience, cutting efficiency, and stability, this equipment provides a superior film cutting experience for you and your clients.

Film cutting machine

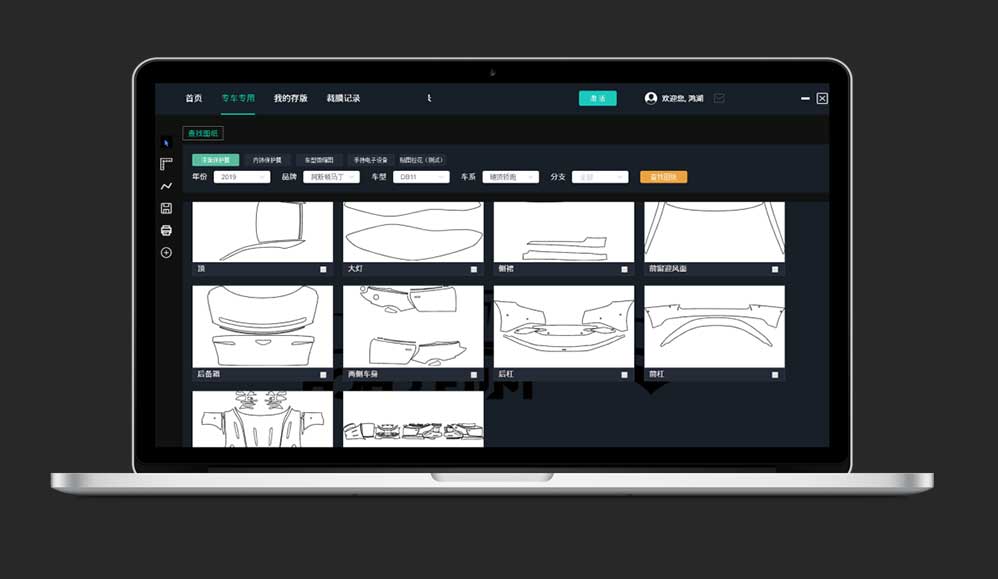

Vehicle-specific data software

Technically, Magicar’s dedicated system uses 3D scanning of the actual vehicle to ensure data accuracy from the source of collection. The process from software installation to printing and cutting is simple and clear.

Massive Data

The system covers data on paint protection films from hundreds of different brands worldwide, spanning various years and models (including interiors). It includes not only mainstream and mature vehicle models but also continuously updates data for new brands and models.

Precise Templates

After mapping 3D scanned vehicle data to 2D planes, technicians thoroughly check and optimize the data to avoid issues related to uncontrollable accuracy loss during the mapping process, ensuring a seamless and precise fit.

User-Friendly Operations

The system supports custom edge wrapping editing and has pre-processed layouts for both full vehicle and edge wrapping. Users can save a significant amount of time and improve efficiency by making slight modifications or using the pre-set layouts directly without complex operations.

Cost Reduction

Based on actual installation experiences, using our specialized vehicle system can save an average of 20% per roll of film, approximately 3 meters in length. The system also reduces installation time per vehicle by around 30% compared to manual cutting.