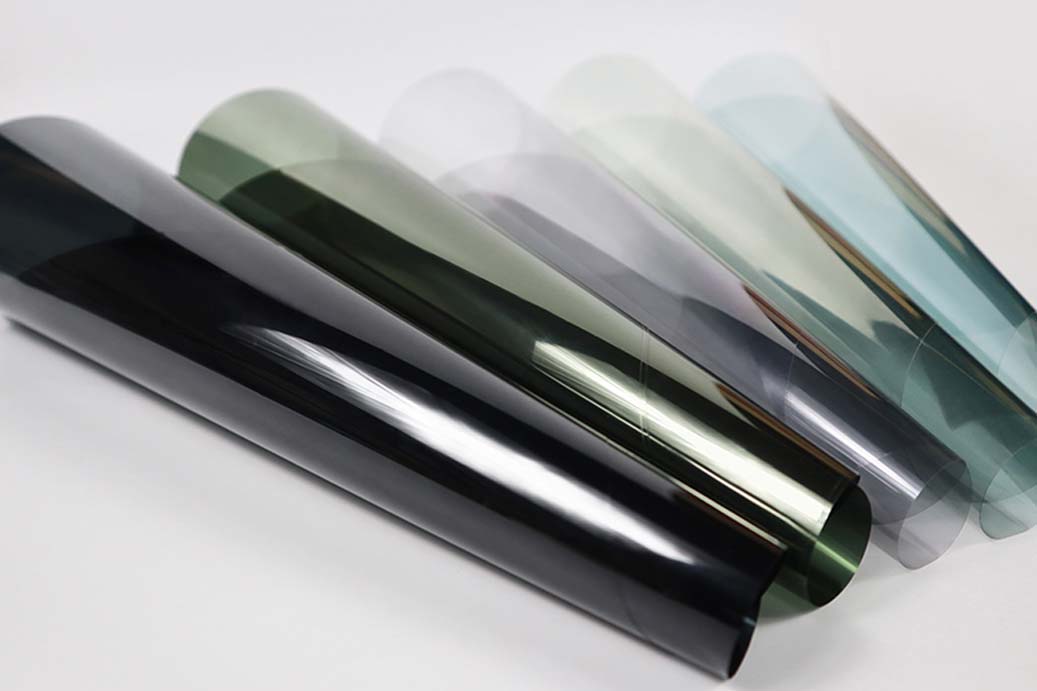

Solar film, also known as thermal insulation film, is often produced in modern solar film production technology by vacuum spraying or magnetron sputtering technology to make multi-layer to dense high insulation metal film layers of aluminum, gold, copper, silver and other metals.

On December 6, 1966, 3M Company in the United States obtained the world’s first patent for solar insulation film.

Many modern buildings use glass curtain walls, large glass, and floor to ceiling glass doors (balconies), which not only improve the room landscape but also increase the amount of solar radiation heat entering the room, increasing the electricity consumption of room air conditioning. Air conditioning is the top killer of building energy consumption, accounting for 20% to 50% of building energy consumption.

In order to solve the above problems, the United States has developed a solar insulation film, which has functions such as thermal insulation, energy conservation, UV resistance, aesthetics and comfort, safety and explosion prevention, effectively and conveniently solving many problems caused by glass, just like when a car collides, the film will stick the glass together.

The film pasted on the surface of car glass is commonly known as car film or explosion-proof film, initially referred to as solar film. Therefore, as the name suggests, car film is used to deal with the scorching summer sun and ultraviolet light. In addition to thermal insulation and light isolation, explosion-proof film also has explosion-proof function. High quality explosion-proof film is made of special polyester film as the substrate, which has strong toughness and is combined with special pressure-sensitive adhesive. In case of accidents, the glass will break and be firmly adhered by the car film without splashing and injuring people. The car explosion-proof film also has the function of one-way perspective and reducing glare.

We can make simple judgments on the performance of a computer based on parameters such as CPU, memory, and graphics card. The same goes for car insulation films. How to judge the performance of car insulation films and how to choose a car insulation film? We only need to look at the four major parameters, which are transmittance, insulation rate, UV blocking rate, and infrared blocking rate.

1. Transmittance (visible light transmittance)

Transmittance, also known as visible light transmittance, the higher the transmittance, the clearer the field of view! Car film has certain requirements for light transmittance, mainly for the front gear. In China, traffic laws stipulate that the light transmittance of the front windshield of a car cannot be lower than 70% for safety reasons! Of course, this is limited to the front gear, and there are no requirements for the side gear, rear gear, and sunroof of the vehicle.

So, in the selection of car thermal insulation film, only films with a transmittance of not less than 70% can be used to install the front windshield, and dark thermal insulation film is the most taboo to apply to the front windshield.

2. Insulation rate (total solar energy barrier rate)

Generally speaking, insulation films with a thermal insulation rate of 60% on the market are already good products. If the product itself claims to have an insulation rate of up to 80%, or even 90%, consumers need to have an extra mindset.

It is worth noting that the insulation rate of the front gear will not exceed 70%! Why is this saying? Just calculate and you’ll know! The main components and heat proportion of sunlight are visible light heat accounting for 43%, infrared light 48.3%, and ultraviolet light 8.7%; The front windshield requires a light transmittance of no less than 70%, which means that the visible light transmittance must be at least 70%. 70% of the visible light brings 70% * 43%=30.1% heat. The meaning is that if the transmittance is not less than 70%, it means that at least 30.1% of the heat cannot be blocked!

3. UV blocking rate

The UV blocking technology of automotive insulation films is already very mature. For generally high-quality films, this indicator is generally not less than 98%, and can reach up to 99.9%. High UV blocking rate can effectively prevent people inside the car from being exposed to excessive UV radiation, causing skin burns, and also protect the car’s audio system from being damaged by the sun. Many low-quality films do not have this indicator or are far below the 98% standard. This is also the main basis for the warranty period of the product.

4. Infrared insulation rate

As mentioned above, the composition and energy proportion of solar rays can be completely blocked by the heat of ultraviolet rays. Visible light has a hard indicator of over 70%, so the remaining infrared blocking has become the main battlefield for automotive insulation films. The higher the infrared blocking rate, the better the thermal insulation performance of the product under the same clarity.

According to the different processing methods for infrared radiation, the thermal insulation films on the market can be divided into two major camps: a metal film that reflects infrared radiation for insulation, and a heat absorbing film that absorbs infrared radiation for insulation. In terms of effectiveness, reflective insulation is more excellent and long-lasting than absorption insulation.